Shoa likarolo lahla

Tlhaloso e Khutšoanyane:

Shoa likarolo lahla li entsoe ka zinki, koporo, aluminium, magnesium, lead, tin le lead alloys tin le lits'epe tse kopantsoeng tsa tsona, tse qhibilihisitsoeng ka mocheso o phahameng ebe li kenoa ka mokoting oa hlobo ebe li pholile tlasa khatello

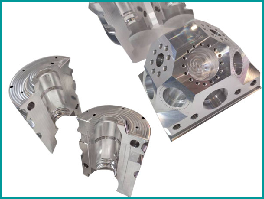

Tšepe shoa lahla karoloke mofuta oa likarolo lahla khatello. Ke mofuta oa khatello ea foromeletsoeng mochini shoela'ng-foromeletsoeng mochini hlomelloa le shoela'ng foromeletsoeng. E sebelisa tšepe tse kang koporo, zinki, aluminium kapa aluminium alloy e futhumetseng ho fihlela boemo ba mokelikeli ho tšela koung ea phepelo ea mochini o lahlang. Kamora ho lahla mochini ka mochini o shoang, o ka lahla koporo, zinki, likarolo tsa aluminium kapa likarolo tsa aluminium tse nang le sebopeho le boholo ba lefu. Likarolo tse joalo hangata li bitsoa likarolo tse lahlang lefu. Ho lahla li-die ho na le mabitso a fapaneng libakeng tse fapaneng, joalo ka likarolo tsa ho lahla, khatello ea likarolo, likarolo tse laoloang, die-casting aluminium, zinc e lahla, koporo e shoang, koporo ea koporo, zinc-casting, aluminium shoa-lahla aluminium shoela'ng-foromeletsoeng, aluminium shoela'ng-foromeletsoeng motsoako, likarolo aluminium motsoako shoela'ng-foromeletsoeng, joalo-joalo

Menyetla ea tšepe shoa likarolo lahla:

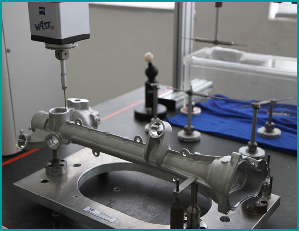

(1) Ho nepahala ha mahlakore a mabeli (ho latela lisebelisoa tsa ho lahla, empa 2.5cm ea pele (0.004 inch bakeng sa 1 inch ea pele) hangata ke 0.1mm, 0.02mm bakeng sa keketseho e 'ngoe le e' ngoe ea 1cm (0.002 inch bakeng sa keketseho e ngoe le e ngoe ea 1 inch).

(2) Boreleli bo boreleli (RA 1 - 2.5 microns kapa 0.04 - 0.10 microns). Mabota a mosesaane a ka akheloa ha a bapisoa le lehlabathe le ho lahleloa ruri (hoo e ka bang 0.75 mm kapa 0.030 ho). Lisebelisoa li ka lahleloa ka hare (mohlala, ho kenya likhoele, lintho tse futhumatsang le libaka tse nang le matla a maholo). Fokotsa kapa ho felisa ts'ebetso ea bobeli ea machining. Lebelo la tlhahiso e potlakileng. Matla a ho qhekella a fihlile ho 415 MPa (60 Ksi).

Go tlhoka mesola tsa tšepe shoela'ng foromeletsoeng

(1) Litsenyehelo tsa capital li holimo haholo. Ha ho bapisoa le mekhoa e meng ea ho betsa, lisebelisoa tse hlokahalang tsa ho betsa, hlobo le likarolo tse amanang le tsona li theko e boima haholo. Ka hona, molemong oa ho etsa die die ho lahla ts'ebetso ea moruo, ho hlokahala palo e kholo ea tlhahiso.

(2) Bakeng sa tšepe e phallang haholo feela, boima ba ho lahla bo tlameha ho ba lipakeng tsa 30 g (1 oz) le 10 kg (20 lb).

(3) Ka mokhoa o tloaelehileng oa ho lahla li-die, ho tla ba le palo e nyane ea masapo ha a betloa la ho qetela. Sena se ka thibela kalafo ea mocheso kapa ho tjheseletsa, hobane mocheso o tla baka ho hola ha khase ka masoba, e tla baka mapatso a manyenyane le ho ebola bokaholimo likarolong, ka hona, bothata bo amanang le ho betloa ha lefu ke hore e sebetsa feela likarolong tse nang le bonolo bo amohelehang. Likarolo tse hlokang ho thatafala (ka ho thatafatsa kapa ho thatafatsa ha linyeoe) le ho futhumatsa ha li lahleloe ka hlobo.

Kopo ya likarolo tšepe shoa lahla:

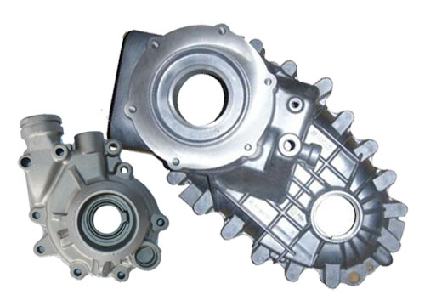

Ka lebaka la melemo ea likarolo tsa tšepe tsa tšepe, e 'nile ea sebelisoa haholo, haholoholo tlhahiso ea bongata ba li-casters tsa alloy tse se nang mafura. Tlhahisong ea li-die-casting, li-aluminium alloy die-casting li etsa karolo e kholo ka ho fetisisa, e ikarabellang ho 30% - 50%; zinc alloy die-casting ke ea bobeli; likarolo tsa koporo tsa koporo tsa koporo li etsa 1% - 2%. Likarolo tse sebelisoang ka ho fetesisa tsa die die ke tlhahiso ea likoloi le literekere, e lateloa ke tlhahiso ea lisebelisoa le indasteri ea lisebelisoa tsa elektroniki, le mechini ea temo, indasteri ea ts'ireletso ea naha, khomphutha, lisebelisoa tsa bongaka le liindasteri tse ling tsa tlhahiso. Likarolo tse hlahisoang ke mokhoa oa ho lahla li-enjene li kenyelletsa enjene ea silindara, sekoaelo sa silindara, lebokose la li-gear, sekoaelo sa enjene, khetla le bracket ea seletsa le kh'amera, kopanelo ea lipeipi, likere, jj

likarolo tsa tšepe tsa tšepe

Aluminium shoa lahla dilenaneo matlo

Industrial aluminium die ho lahla karolo

Auto aluminium die ho lahla matlo

Zinc shoa lahla matlo

Zinc shoa lahla botlaaseng

Sebetsa ka ho nepahetseng zinki shoa lahla oache matlo

Shoa lahla khamera matlo a elektronike

Magnesium alloy die casting case / cover

Shoa lahla likarolo lebone

Die-lahla belofo & pompo 'mele

Likarolo tsa mokhabiso o shoang

Shoa lahla likarolo koporo

Likarolo tsa tšepe tse laoloang ka tšepe li ka etsoa joalo ka likarolo tsa koloi tse shoang, li-fittings tsa enjene ea koloi, likarolo tsa moea tse shoang, tse lahlang hlooho ea peterole mochini oa silindara, letsoho la tšepe la tšepe, Likarolo tsa motlakase tse laoloang ke die, likarolo tsa sekoaelo sa makoloi tse shoang, shoa lahla likhetla, likarolo tsa pompo tse shoang, likarolo tsa mochini o shoang, likarolo tsa mekhabiso e shoang, likarolo tsa likarolo tsa likarolo tsa tšepe, lebili la likarolo tse ling. Ka tlhahiso ea lapeng Ka nts'etsopele ea indasteri ea lisebelisoa, boemo ba lisebelisoa tsa mochini oa ho lahla li ntlafalitsoe haholo, mefuta ea likarolo tse ka etsoang e atolositsoe, mme ho nepahala, ho rarahana le boholo ba likarolo tse ka bang teng shoa cast le tsona li ntlafalitsoe haholo.

Likarolo tsa tšepe tsa tšepe li ntse li sebelisoa haholo indastering, lifofane, koloi, sekepe, elektroniki, motlakase le liindastering tse ling ka lebaka la melemo ea tsona e ikhethang. Haeba sehlahisoa sa hau se hloka ho sebelisoa, ka kopo ikopanye le rona. Re tla u fa tlhahiso le tšebeletso ea tšepe shoa likarolo lahla ka pelo eohle.