Shoa lahla hlobo

Tlhaloso e Khutšoanyane:

Shoa lahla hloboke mofuta oa thepa ea tšepe foromeletsoeng shoela'ng. Foromo ea die casting e na le hlobo "sekoahelo sa halofo ea sekoahelo" 'me e' ngoe "ejector shoa halofo.

Mefuta ea ho lahla e sebelisoa haholo bakeng sa ho etsa likarolo tsa tšepe tse se nang litšepe tse nang le sebopeho le sebopeho se rarahaneng. Joalo ka tlhahiso ea bongata ba motsoako oa aluminium, motsoako oa zinc, motsoako oa magnesium le likarolo tsa koporo, tse sebelisoang haholo koloing, elektroniki, lisebelisoa tsa motlakase, thepa ea ka tlung, bongaka le lihlahisoa tse ling.

Ke eng shoa lahla hlobo

Shoa lahla ke lebitso le lekhuts'oane la khatello ea khatello. Ke mokhoa ho tlatsa lehare la shoa lahla hlobo ka mokelikeli kapa seka mokelikeli oa tšepe tlasa khatello e matla

ka lebelo le phahameng 'me u tiise ka potlako ho fumana ho betsa. Hlobo e sebelisoa e bitsoa shoa lahla hlobo shoa.

Mefuta ea hlobo e shoang e lahleloa

Ho ea ka ts'ebeliso, e ka aroloa likarolo tsa likarolo le likarolo tse khabisitsoeng.

Ho ea ka boemo ba kopo, e ka aroloa ka koloi e lahla hlobo, 3C sehlahisoa se shoang se lahla hlobo, toy e shoang e lahla hlobo, jj.

Ho ea ka litšobotsi tsa sebopeho le botenya leboteng, e ka boela ea aroloa ka tšesaane-marako shoa-lahla hlobo, lebokose shoela'ng-lahla hlobo le disk shoa-lahla hlobo

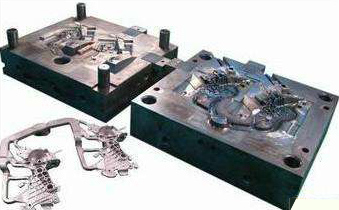

Mochini oa ho lahla, mochini o lahlang li-die le li-die-casting ke likarolo tse tharo tsa tlhahiso ea li-die-casting, e 'ngoe ea tsona e bohlokoa haholo.

Mofuta oa mochini o shoang o lahla, o shoa likarolo tsa moaho, ts'ebetso ea ho lahla le moaho oa fektheri o its'etleha holima thepa ea mofuta oa die-casting, ka hona, tlhophiso ea die-casting die e ea ka motsoako oa alloy e loketse ts'ebetso ea tlhahiso. ba shoa-lahla hlobo ka aroloa hlobo aluminium shoela'ng-lahla hlobo, zinki motsoako shoa-lahla hlobo, magnesium motsoako shoa-lahla hlobo le koporo motsoako shoa-lahla hlobo. Lintlha li tjena:

1) .Aluminium shoa lahla hlobo

2) .Zinc shoa lahla hlobo

3) .Magnesium alloy e shoang e lahla hlobo

4) .Copper motsoako shoa-lahla hlobo

5) .Sintering hlobo

Aluminium die e lahla hlobo

Zinki shoa lahla hlobo

Shoa lahla hlobo sebopeho

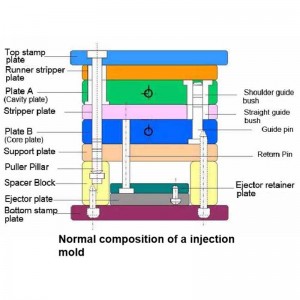

Sebopeho sa hlobo e lahlang e ka aroloa likarolo tse peli:

Ema hlobo halofo:Ho ts'oaroa holim'a poleiti e ts'oaroang ea hlobo ea mochini oa ho lahla, o nang le sekontiri se kopantsoeng le nozzle kapa kamore ea khatello;

Nkehang hlobo:Ho tsitsisoa poleiti e ntseng e hola ea mochini o lahlang, ebe o fallisoa ka poleiti ea ho bula le ho koala hlobo. Ha u koala hlobo, mohala oa hlobo le sistimi ea ho betla lia bōptjoa, 'me tšepe ea mokelikeli e tlatsa lehare ka tlas'a khatello e phahameng. Ha u bula hlobo, halofo ea hlobo e tsamaeang le mofuta o emisitsoeng oa hlobo o arotsoe, mme ho lahla ho sutumelloa kantle ka thuso ea mochini oa ejection o behiloeng holima halofo ea hlobo.

Sebopeho sa lefu la ho lahla se kenyelletsa lits'ebetso tse latelang ho latela mesebetsi ea sona:

1) Cavity: bokaholimo ba sefahleho (sleeve ea sefahleho); Core: heke e kahare ea bokaholimo ba kahare.

2) Likarolo tsa tataiso: poso ea tataiso; sleeve ea tataiso.

3) Qalisa mochini Push molamu (thimble), reset rod, sutumelletsa molamu poleiti poleiti, sutumelletsa poleiti, sutumelletsa poleiti tataiso poso, sutumelletsa poleiti tataiso sleeve.

4) Lehlakoreng konokono hula mochine Boss, lesoba (lehlakoreng), chesele le literata, moedi selemo, nsete.

5) khaphatseha oona tsamaisong khaphatseha ka senoelong, ho qeta monono ka senoelong.

6) likarolo tse tšehetsang.

Poleiti e emisitsoeng ea hlobo ea hlobo, poleiti e tsamaeang ea hlobo, sethopo sa mosamo (kopano, boemo, ts'ebetso ea ho kenya).

Phapang pakeng tsa shoa lahla hlobo le hlobo polasetiki:

1.The khatello ea ente ea shoela'ng foromeletsoeng shoela'ng e kholo. Ka hona, template e lokela ho ba e tenya. Thibela deformation.

2. Heke ea shoa lahla hlobo e fapane le ea hlobo ea ente. Khatello e phahameng ea phallo ea lintho tse bonahalang e tla senyeha ke khoune e arohaneng.

3.Mokokotlo oa lefu lahla li-die ha o hloke ho thatafatsoa. Hobane thempereichara e ka cavity shoa ba fetang 700 ℃. Ka hona, sebopeho se seng le se seng se lekana le ho tima ka ho le leng. Lehare le tla thatafala le ho feta. Sebopeho se akaretsang sa ente se lokela ho tima ho feta hrc52.

4. Ka kakaretso, lesoba la shoa-lahla die e hloka kalafo ea nitriding. Thibela motsoako ho khomarela hlobo ea mokoti.

5. Ka kakaretso, ts'enyeho ea shoa lahla li-die li batla li le kholo. Karolo e kantle ka kakaretso e putsoa.

6. Ha ho bapisoa le hlobo ente. Tlhaloso e loketseng ea karolo e tsamaeang ea die die cast (joalo ka sekonopo se hulang) e lokela ho ba kholo. Hobane mocheso o phahameng oa ts'ebetso ea ho lahla shoa o tla baka katoloso ea mocheso. Haeba tumello e le nyane haholo, hlobo e tla tšoarella.

7. Karolo e arohaneng ea die-casting die e na le litlhokahalo tse phahameng tse tšoanang. Hobane fluidity ea alloy e betere haholo ho feta ea polasetiki, ho kotsi haholo bakeng sa mocheso o phahameng le khatello ea thepa e phahameng ho fofa ho tsoa bokaholimo ba karohano.

8. hlobo ea ente hangata e itšetleha ka thimble. Karolo e arohaneng e ka tsoa. The hlobo shoa-lahla lokela ho fuoa le sekotjana sa ho qeta monono le mokotla slag bokella (ho bokella batang hlooho lintho tse bonahalang).

9. Ho theha ha ho lumellane. Lebelo la ente la li-casting tsa die die li potlakile. Mohato oa pele oa khatello ea ente. Hlobo ea polasetiki hangata e arotsoe ka ente e 'maloa, khatello.

10. Sebopeho se shoang ke lipoleiti tse peli (ha ke so bone hlobo ea poleiti e shoeleng hona joale) lesoba le le leng. Mefuta e fapaneng ea lihlahisoa tsa hlobo ea polasetiki li fapane. Mefuta e 3 ea poleiti e tloaelehile. Palo le tatellano ea ho buloa li tsamaellana le sebopeho sa lefu. Square thimble ha se hangata e sebelisoa ka shoa lahla hlobo. Moqomo.

11. Pin e sekametseng (mocheso o phahameng le tharollo e ntle ea metsi) e bonolo ho jeme, e lebisang tlhahisong e sa tsitsang ea hlobo. Ho phaella moo, hlobo ea polasetiki le hlobo e lahlang li entsoe ka tšepe e fapaneng; hlobo ea polasetiki ka kakaretso e sebelisa 45 × tšepe, T8, T10 le tšepe e 'ngoe, ha e ntse e lahla

Khamphani ea Mestech e shebile haholo tšimong ea tlhahiso e nepahetseng ea hlobo le likarolo tsa eona bakeng sa lilemo tse fetang 10, e nang le theknoloji ea indasteri e tsoetseng pele le boiphihlelo bo ruileng ba tlhahiso ea hlobo. Lihlahisoa tsa k'hamphani ke lihlahisoa tsa polasetiki haholo kapa thepa ea khetla joalo ka lihlahisoa tsa dijithale tsa elektroniki, lisebelisoa tsa bongaka, lihlahisoa tsa masea, jj. Hammoho le lihlahisoa tsa polasetiki tse kang lihlahisoa tsa lapeng le likarolo tsa likoloi. Khamphani e na le bokhoni bo matla ba moralo oa sebopeho le moralo oa hlobo, e ka fang bareki litlhahiso tse ntlafalitsoeng haholoanyane ka sebopeho sa sehlahisoa le merero e utloahalang haholoanyane ea hlobo