Metal tapa

Tlhaloso e Khutšoanyane:

Ho hatakela tšepe ke ho sebelisa litebele le ho shoa ho holofala kapa ho robeha tšepe e sa hloekang, tšepe, aluminium, koporo le lipoleiti tse ling le lisebelisoa tsa kantle ho naha ho fihlela sebopeho le boholo ba ts'ebetso.

Tsamaiso tapa ka aroloa thulaganyou e karohano le eaba ba etsa (ho akarelletsa le ba kobang, kotokaka le eaba ba etsa). Ts'ebetso ea karohano ke ho arola karolo ea litempe le e sa koahetsoeng ka mohala o itseng molemong oa ho hatakela, 'me boleng ba karolo e arohaneng ea karolo ea litempe bo tlameha ho fihlela litlhoko tse itseng; tshebetso eaba ba etsa ke ho etsa tapa letho polasetiki deformation tlas'a boemo ba ha ho na tšenyo e, le fetola e be sebopeho hlokahala sehlahisoa se felile, 'me hape kopana ditlhoko tsa mamello tlhakore le likarolo tse ling.

* Ho latela maemo a mocheso o hatakelang, ho na le mekhoa e 'meli ea ho tapa ho bata le ho chesa ho chesang. Sena se ipapisitse le matla, polasetiki, botenya, degree deformation le lisebelisoa tsa lisebelisoa, 'me boemo ba pele ba kalafo ea mocheso le boemo ba ho qetela ba ts'ebeliso ea thepa li lokela ho tsotelloa. 1. Cold tapa tšepe e sebetsa ka mocheso kamore, ka kakaretso ho hlokehang ho botenya ba ka tlase ho 4mm letho. E na le melemo ea ho se futhumale, ha ho na letlalo la oxide, boleng bo botle ba bokaholimo, ts'ebetso e bonolo le theko e tlase. Bothata ke hore ho na le ts'ebetso e thatafatsang mosebetsi, e etsang hore tšepe e lahleheloe ke bokhoni ba ho fetoha. Botenya ba sekheo bo tšoana 'me ha ho hlokahale mengoapo. 2. Ho chesa tšepe ho chesa ho isa mochesong o itseng. Melemo ke hore e ka felisa khatello ea maikutlo ea kahare, ea qoba ho thatafala ha mosebetsi, ea eketsa polasetiki ea lintho tse bonahalang, ea fokotsa ho hanyetsa deformation le ho fokotsa ts'ebeliso ea matla ea lisebelisoa

* Lintlha tse tharo tsa mantlha tsa sistimi ea tlhahiso ea litempe: shoa, tobetsa le tšepe

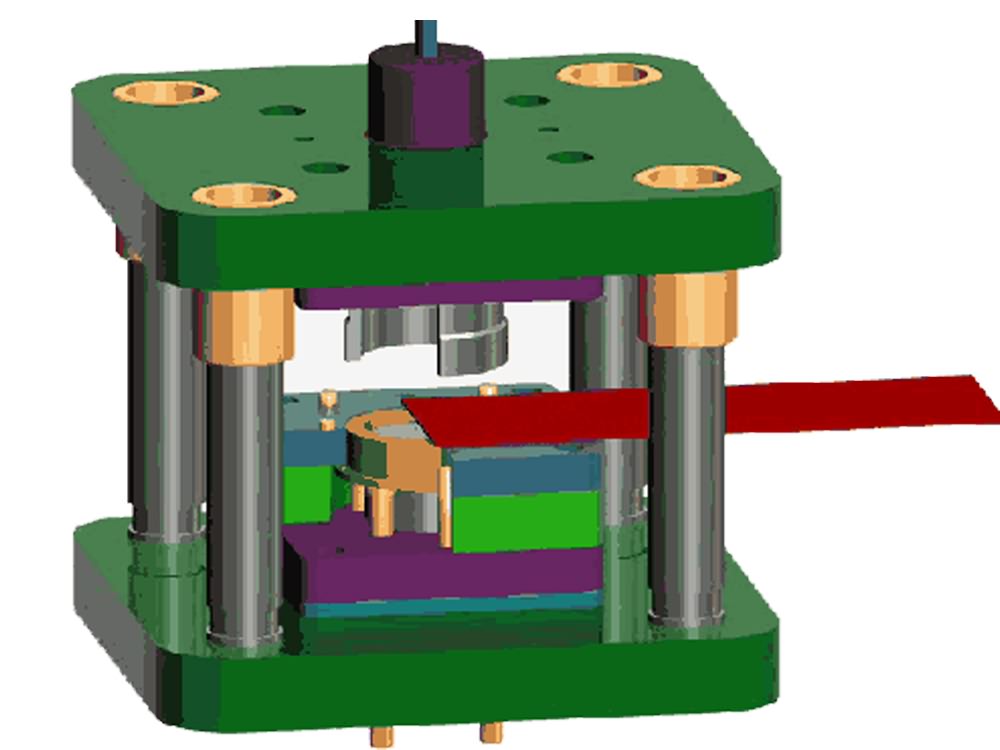

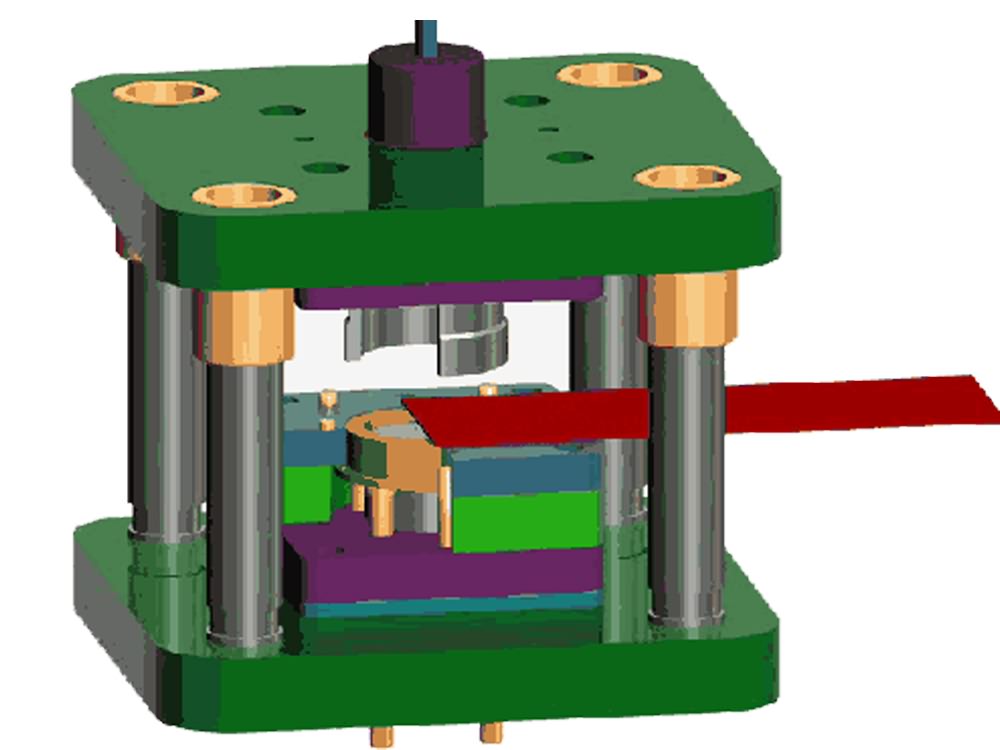

1. Ho otla ka litebele Die Die ke sesebelisoa sa bohlokoa se hlahisang litempe. Ho na le mefuta e meraro ea stamping die: bonolo die, die e tsoelang pele le komponeng shoa.

Die Die ke sesebelisoa sa bohlokoa sa tlhahiso ea litempe. Ho na le mefuta e meraro ea stamping die: bonolo die, die e tsoelang pele le komponeng shoa.

(1) Lefu le bonolo: lefu le bonolo ke lefu le phethelang ts'ebetso e le 'ngoe ka leqeba le le leng la boralitaba. E loketse tlhahiso e nyane ea methapo ea likarolo tse bonolo tsa sebopeho.

(2) Lefu le tsoelang pele: leqeba le le leng la khatiso, lefu le phethelang lits'ebetso tse 'maloa tsa ho tapa likarolong tse fapaneng tsa lefu ka nako e le' ngoe le bitsoa die e tsoelang pele. Tsoelang pele shoela'ng ke a loketse bakeng sa phahameng bokgoni tlhahiso ea jarolla ka ho iketsa.

(3) Compound die: ka stroke, karolong e ts'oanang ea lefu ho phethela lits'ebetso tse 'maloa tsa ho tapa ka nako e le' ngoe, e tsejoang ka hore ke sehlopha se shoang. Motsoako oa lefu o loketse likarolo tsa ho tapa tse nang le sehlahisoa se seholo le ho nepahala ho phahameng.

2. Mochini o otlang ka litebele

Tapa tlhahiso ke haholo-holo bakeng sa poleiti. Ka hlobo, e ka etsa ho koala letho, ho phunya, ho etsa, ho taka, ho phethela, ho koala hantle, ho betla, ho riveting le likarolo tsa extrusion, jj, tse sebelisoang haholo masimong a fapaneng. Mohlala, re sebelisa li-switch, sokisi, linoelo, lik'habote, lijana, mabokose a likhomphutha, le lifofane tsa limisaele Ho na le lisebelisoa tse ngata tse ka hlahisoang ka setebele ka hlobo. Hona le mefuta e mengata ea mechini e otlang.

(1) Mechini ea khatiso ea matla ea "Mechanical" e na le seteraeke se tsitsitseng, lebelo le fetohang le tlhahiso e tlase. Lebelo le phahameng haholo makhetlo a 180 / min.

(2) Mochine oa khatiso oa Hydraulic

Punch ea hydraulic e ka fetola leqhubu le hatakelang ka phunyang ea haeteroliki ho ntlafatsa tlhahiso. Lebelo le phahameng ka ho fetisisa le ka fihla makhetlo a 1000 / min. Mathata ke tšebeliso e phahameng ea motlakase, litlhoko tse phahameng tikolohong le mosebetsi o boima oa tlhokomelo.

(3) Palo ea taolo ea turret punch e tobetsa

U sebelisa servo motor ho khanna hlooho, tlhahiso e phahame, ho fihlela makhetlo a 800 / min. Ts'ebeliso e nyane ea motlakase, tlhokomelo e bonolo le boholo bo bonyenyane. Ka hona, e sebelisitsoe ka mafolofolo.

Bakeng sa litempe tse tloaelehileng tsa tšepe, boholo ba tsona li sebelisa litebele. Ho latela mokelikeli o fapaneng o sebelisoang mechineng ea hydraulic, ho na le mechini ea hydraulic le mechini ea hydraulic. Boholo ba tsona li sebelisa mechini ea haeteroliki, ha mechini ea hydraulic e sebelisoa haholo bakeng sa mechini e meholohali kapa e khethehileng. Ka lebaka la melemo ea eona e ikhethang, servo motor punch e ntse e sebelisoa le ho feta.

Thepa 3.Stamping Boitsebiso bo tapa tsa likarolo ka kakaretso poleiti. Lisebelisoa tse khethiloeng bakeng sa moralo oa sehlahisoa li tla fihlela ts'ebetso ea ts'ebeliso ea sehlahisoa, joalo ka ho ba thata, matla le ho khanna ha sehlahisoa. Ka lehlakoreng le leng, e lokela ho fihlela litlhoko tsa polasetiki, boleng ba bokaholimo le botenya ba ts'ebetso ea ho tapa. Moralo oa likarolo tsa litempe o lokela ho nahana ka botlalo ka litšobotsi tsa ts'ebetso ea ho tapa, radius e kobehileng, lesoba la ho beha, tokiso, botebo ba ho taka, jj. le tlaase deformation hanyetsa, 'me a loketse bakeng sa tapa batang. (1). Lisebelisoa tsa tšepe: SPCC / SPCD / spce, SECC / SECD / sece, SGCC, sgld, Sus (2). Aluminium motsoako: al1050p, al1100p, al5020 (3). Motsoako oa koporo: Pb phosphor boronse, HBS matla a phahameng a koporo (4). Motsoako oa nickel oa Cupro.

* Theknoloji ea kalafo ea bokaholimo ea likarolo tsa tšepe ha e qeta ho sebetsoa le ho bōptjoa, e hloka ho fetola bokaholimo ba tšepe, e khabise bokaholimo, le ho ntlafatsa likarolo tsa mochini le tsa 'mele tsa tšepe. Ts'ebetso ena e bitsoa kalafo ea tšepe ea tšepe. Morero oa kalafo ea tšepe e arotsoe ka mekhahlelo e mene:

(1) E ntle

(2) Tšireletso

(3) Thepa e khethehileng ea bokaholimo

(4) Ntlafatsa thepa ea mochini, joalo ka ho tsofala, ho tlotsa, joalo-joalo.

* Mofuta oa kalafo ea bokaholimo Electroplating (zinki, koporo, nikele, chromium, khauta, silevera), ho fafatsa ka motlakase, ho penta ka fafatsa, electrophoresis, khatiso ea skrine ea silika, anodizing, blackening, passivation

* Ho hatakela tšepe ea lakane ho bonolo ho fihlella tlhahiso e ntle haholo ka ho sebelisa mechini le boiketsetso ho bonolo ho elelloa ho sebelisa mechini le boiketsetso ka ts'ebetso e phahameng ea tlhahiso; likarolo tse hatakeloang li na le boholo bo nepahetseng le ho fapanyetsana hantle; bokaholimo bo boreleli ebile bo boreleli, hangata bo se na mochini. E sebelisoa haholo ho likoloi, lisebelisoa tsa motlakase, seletsa, lifofane le liindasteri tse ling tsa tlhahiso.

Mestech eu fa likarolo le litšebeletso tsa tšepe. Haeba u na le tlhoko kapa u hloka ho tseba ho eketsehileng, ka kopo ikopanye le rona.