Ts'ebetso ea ho lahla

Tlhaloso e Khutšoanyane:

Ts'ebetso ea ho lahla ke ts'ebetso eo zinc, koporo, aluminium, magnesium, lead, tin le lead tin tin li-alloys le tsona li qhibilihisoang mocheso o phahameng ebe li kenngoa ka mokokotlong oa hlobo, ebe li pholile tlasa khatello ea ho fumana likarolo.

Mocheso sebetsa tsa bao e seng ferrous tšepe shoela'ng foromeletsoeng e tlaase haholo ho feta ea ho betsa tšepe, le e lekanang thepa foundry le ditlhoko thulaganyou e bonolo, 'me tse nyenyane. Tlhahiso ea die lahla e ka fumana boleng bo botle ba bokaholimo le ho nepahala ha tlhakore, haholo-holo e loketseng tlhahiso e kholo ea likarolo tse nyane le tse mahareng, tse fanang ka tšehetso e ntle ea karolo bakeng sa lisebelisoa tsa sejoale-joale tsa elektroniki, lisebelisoa tsa motlakase, likoloi, lisebelisoa tsa bongaka, lisebelisoa le kithen lisebelisoa. Li-alloys tse fapaneng tsa tšepe li na le sebopeho se fapaneng haholo ts'ebetsong ea ho lahla. Karolo ea bona e tlase le moralo oa bonyane li fapane, mocheso o qhibilihisang o fapane, qetello ea bokaholimo e fapane, Kahoo ho molemo ho kenyelletsa sehlopha sa rona sa baenjiniere pele ho nako nakong ea moralo oa moralo ho sebelisa boiphihlelo ba rona ka moralo oa tlhahiso.

Ho na le lintlha tse hlano tse ka sehloohong ts'ebetsong ea tšepe ea tšepe:

1.Die lahla lintho tse bonahalang;

Mefuta ea 2.

3.Die lahla mochini;

4.Die foromeletsoeng hlobo;

5.Post Processing le Qetella bakeng sa Likarolo tsa Die Casting

Tšepe shoa lahla thulaganyou eke ts'ebetso ea ho kopanya khatello, lebelo le nako ka ho sebelisa likarolo tse tharo tsa mochini, hlobo le alloy. Bakeng sa tšepe sebetsa chesang, boteng ba khatello ea ke tšobotsi e ka sehloohong ea thulaganyou e shoela betsa eo e fapane le mekhoa e meng foromeletsoeng. Khatello ea foromeletsoeng ke mokhoa o khethehileng foromeletsoeng le ka tlaase ho moo 'me ha ho itšeha, e leng e ntshetswa pele ka potlako theknoloji ea kajeno tšepe e lokisa. Ke ts'ebetso ea ho tlatsa hlobo ka tšepe e qhibilihisitsoeng tlasa khatello e phahameng le lebelo le phahameng, ebe e etsa ho lahla ka crystallization le solidification tlasa khatello e phahameng. Khatello e phahameng le lebelo le phahameng ke litšobotsi tse ka sehloohong tsa ho betsa lefu. Khatello e sebelisoang hangata ke li-megapascals tse mashome, lebelo la ho tlatsa (lebelo le ka hare la heke) le ka ba 16-80m / s, mme nako ea ho tlatsa mokelikeli oa tšepe ka mokokotlong oa hlobo e khutšoane haholo, e ka bang 0.01-0.2s. Metal die casting ke mochini o laolang tšepe o khetholloang ka ho qobella tšepe e qhibilihisitsoeng tlasa khatello e matla hore e be mokoti oa hlobo. Sekoti sa hlobo le mokokotlo o entsoe ka ho shoa ha tšepe e thata e entsoeng ka sebopeho mme e sebetsa ka mokhoa o ts'oanang le hlobo ea ente nakong ea ts'ebetso. Ho ipapisitsoe le mofuta oa tšepe e akheloang, ho sebelisoa mochini o chesang kapa o batang.

MESTECH e fana ka likarolo tsa shoa tsa likarolo tsa zinc, alloyum aluminium le magnesium alloy. Hobane lisebelisoa tsena tse tharo ke lisebelisoa tse sebelisoang ka ho fetesisa tse shoang tse laoloang hajoale.

Zinki motsoako litšobotsi:

--- Matla a phahameng le boima

--- Ho khanna hantle ha motlakase

--- High mogote conductivity

--- Lisebelisoa tse theko e tlase

--- Ho nepahala ka mokhoa o phahameng le botsitso

--- Khabane tse ntle tsa lebota

--- Matla a sebopeho se batang, se nolofalletsang ho ikopanya

--- Litšobotsi tse phahameng tsa ho qeta

Khanyetso e ikhethang ea ts'enyeho - E ka sebelisoa hape ka botlalo

Litšobotsi tsa 2.Aluminium Alloy:

--- Mocheso o phahameng oa ts'ebetso

--- Khanyetso e ikhethang ea ts'enyeho

--- Bobebe

--- Matla le botle bo botle haholo

--- Boima bo botle le karolelano ea matla le boima

--- EMI e ntle le thepa ea ts'ireletso ea RFI

--- Ho khanna hantle haholo

--- Ho khanna ha motlakase o phahameng

--- Litšobotsi tse ntle tsa ho qeta

--- Ho nchafatsoa ka botlalo

3. Litšobotsi tsa motsoako oa Magnesiamo:

--- Ho khanna haholo; motlakase, le mocheso

--- E mamella maemo a phahameng a ho sebetsa

--- Ho nepahala ka mokhoa o phahameng le botsitso

--- Monyako o ikhethang oa lebota

--- Khanyetso e ntle ea ts'enyeho ea tikoloho

--- Litšobotsi tse ntle tsa ho qeta

--- Ho nchafatsoa ka botlalo

1 Tsamaiso ea Hot-Chamber Die Casting

Hot-chamber casting die, eo ka linako tse ling e bitsoang gooseneck casting, ke eona e tsebahalang haholo lits'ebetsong tse peli tsa ho lahla. Ts'ebetsong ena, kamore ea silindara ea mochini oa ente e qoelitsoe ka botlalo ka bate ea tšepe e qhibilihisitsoeng. Sistimi ea phepelo ea tšepe ea gooseneck e hulela tšepe e qhibilihisitsoeng kahare.

Ha ho qoelisoa ka kotloloho bateng e entsoeng ka ho qhibilihisoa ho lumella ente ea hlobo e potlakileng le e bonolo, e boetse e baka ts'oaetso ea ts'enyeho. Ka lebaka la 'nete ena, e chesang-kamoreng shoela'ng thulaganyou e loketse bakeng sa dikopo hore sebelisa tšepe le lintlha tlaase qhibiliha le fluidity phahameng. Lisebelisoa tse ntle bakeng sa ts'ebetso ea ho lahla kamore e chesang li kenyelletsa lead, magnesium, zinc le koporo.

2 Ts'ebetso ea Cold-Chamber Die Casting

Ts'ebetso ea ho lahla kamore e batang e tšoana haholo le ho betloa ha kamore e chesang. Ka moralo o shebaneng le ho fokotsa ts'enyeho ea mochini ho fapana le ts'ebetso ea tlhahiso, tšepe e qhibilihisitsoeng e itšebetsa ka boeona kapa e kenella ka letsoho tsamaisong ea ente. Sena se felisa tlhoko ea hore mochini oa ente o ineloe ka bateng ea tšepe e qhibilihisitsoeng.

Bakeng sa lits'ebetso tse senyang haholo bakeng sa moralo oa qoeliso ea bethe ea kamore e chesang, ts'ebetso ea kamore e batang e ka ba mokhoa o mong o motle. Ts'ebeliso ena e kenyelletsa ho lahla tšepe e nang le mocheso o phahameng o qhibilihang, joalo ka aluminium le aluminium alloys.

3 Ts'ebetso ea khatello ea Low-Pressure Die

Ho lahla khatello e tlase ke mokhoa o loketseng likaroloana tsa aluminium tse lumellanang hantle ho potoloha. Ka mohlala, mabili a likoloi, hangata a iqapetsoe ka ho lahla khatello e tlase ea khatello. Mofuteng ona oa tšebetso, hlobo e lutse ka tsepameng kaholimo ho bate ea tšepe e qhibilihisitsoeng mme e hokahane ka phala ea riser. Ha kamore e hatelloa (hangata e pakeng tsa 20 le 100kPa), tšepe e huleloa holimo ebe e kena ka hlobo. Ho felisoa ha li-feeder tsa mofuta ona oa ts'ebetso ea ho lahla li fana ka chai e ngata.

4 Ts'ebetso ea Vacuum Die Casting

Lephaka khatello ea foromeletsoeng (VPC) ke batlang e le lecha thulaganyou e shoela'ng foromeletsoeng hore lopolla matlafatsoa matla le porosity fokolang haholo. Ts'ebetso ena e ts'oana le ho lahla ka khatello e tlase, ntle le ha libaka tsa hlobo ea tšepe le sesepa sa tšepe e qhibilihisitsoeng li khutlisitsoe. Kamore ea silindara e ka fetoha lephaka, le qobellang tšepe e qhibilihisitsoeng ka lehare. Moralo ona o fokotsa pherekano ebile o fokotsa palo ea kenyelletso ea khase. Lepolanka shoa lahla ke molemo haholo-holo ka dikopo reretsoe ho kalafo mora-lahla mocheso.

5 Mokhoa oa ho Squeeze Die Casting

Squeeze casting e entsoe e le tharollo e sebetsang bakeng sa ho lahla tšepe le lits'epe tse kopantsoeng tse nang le fluidity e tlase. Ts'ebetsong ena, tšepe e entsoeng ka ho qhibilihisoa e tlatsa lefi le bulehileng, le ntan'o pepeta le koalehe, le qobelle tšepe hore e kenelle likarolong tse koahetsoeng haholo tsa letsopa. Ts'ebetso ea ho lahla e fana ka lihlahisoa tse teteaneng haholo mme ke ts'ebetso e tlatselletsang ho kalafo ea mocheso e latelang. Ts'ebetso ena hangata e amahanngoa le aluminium e qhibilihisitsoeng, 'me e sebelisoa lits'ebetsong tse hlokang matlafatso ea fiber.

6 The Semi-Tiileng shoa lahla Process

Ho betla ka seka-solid, eo ka linako tse ling ho thoeng ke Thixoforming, ke ts'ebetso e 'ngoe e fanang ka porosity e nyane le bongata bo boholo. Mochini o seha mosebetsi hore o be li-slugs tse nyane ebe oa futhumala. Hang ha tšepe e se e fihlile phetohong ea mohato pakeng tsa se tiileng le mokelikeli, e leng se hlahisang sebopeho se boreleli, sleeve e thunyang e e qobella mohahong oa hlobo, moo e thatafalang. Molemo oa sena ke ntlafatso e nepahetseng. Lisebelisoa tse se nang litšepe tse kang motsoako oa magnesium le alloyum aluminium hangata li sebelisoa ka ts'ebetso ea semi-solid cast.

7. Mefuta ea Ts'ebetso ea ho lahla Die

Mefuta eohle ea ts'ebetso ea ho lahla e entsoe ka sepheo se ts'oanang kelellong-lahla hlobo ka tšepe e entsoeng ka ho qhibilihisoa. Ho ipapisitse le mofuta oa tšepe e qhibilihisitsoeng, karolo ea jiometri le boholo ba karolo, lits'ebetso tse fapaneng tsa ho betsa li ka fana ka liphetho tse phahameng ho feta mekhoa e meng. Mefuta e 'meli e meholo ea lits'ebetso tsa ho lahla li-hot-kamoreng le kamore e batang ea ho betla. Mefuta e fapaneng ea mefuta ena e 'meli ea ho lahla lefu e kenyelletsa:

Tlaase khatello ea shoela'ng foromeletsoeng

Lephaka shoa lahla

Pepeta shoa lahla

Seka-tiileng shoela'ng foromeletsoeng

1 Hot khatello ea kamoreng shoela'ng foromeletsoeng mochini

Ho latela sebopeho le phallo ea kamore, e ka aroloa ka liforomo tse tshekaletseng le tse emeng. The tsoana le sebopi bakeng sa tšepe entsoeng ka ho qhibilihisoa e khomaretse mochini ke chesang phehella kamoreng, le mochine piston bakeng sa tšepe haeteroliki khatello ea kena hlobo e hlomamisa ka tsoana le sebopi sa. Likamore tse ling tse chesang tse hatellang li sebelisa moea o petelitsoeng ho kenya ka kotloloho khatello ea hydraulic ka hlobo ntle le mochini oa piston.

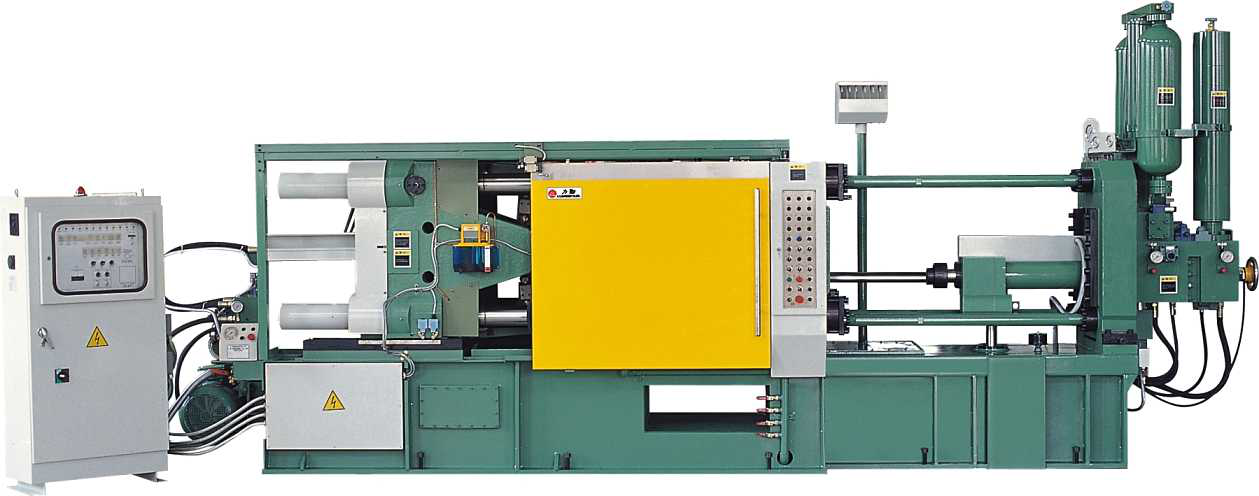

Hot kamoreng shoela'ng foromeletsoeng mochini

The chesang tobetsa kamoreng shoela'ng foromeletsoeng mochini e haholo-holo sebelisoa bakeng sa motsoako shoela'ng-lahla le ntlha tlaase qhibiliha, tse kang zinki, magnesium le thini.

2 Cold khatello ea kamoreng shoela'ng foromeletsoeng mochini

Ho qhibilihisa tšepe ka ntle ho mochini ebe o eketsa tšepe ea mokelikeli ka phapusing ea khatello ka khaba e ka aroloa ka mochini o batang o batang oa terata le mochini o batang o batang o lahla mochini ho latela tataiso ea motsamao oa piston ea khatello.

Ts'epe ea mokelikeli e tlosoa seboping sa mochini o hatellang o batang oa mochini o batang ebe o tšeloa ka phapusing ea khatello. Tšepe e haelloa ke hydraulic ka har'a hlobo ka compression piston, 'me tšepe e setseng e sutumetsoa ka sethunya se seng.

Cold kamoreng shoela'ng foromeletsoeng mochini

Cold kamoreng shoela'ng foromeletsoeng mochini

The tshekaletseng batang kamoreng shoela'ng foromeletsoeng mochini e tšoanang le ea paatsepama, empa motsamao oa piston e tshekaletseng. Mechini e mengata ea sejoale-joale e lahleloang e tshekaletse. Mechini ea Cold-chamber e lahlang li-die-cast e ka shoa-e lahla lisebelisoa tse phahameng tsa ho qhibiliha kapa tšepe e kenang habonolo, joalo ka aluminium, lits'epe tsa koporo, jj.

3.Die lahla mochini.

Mochini oa ho lahla o sebelisoa mochineng oa khatello. Ho akarelletsa ho mefuta e 'meli ea chesang phehella kamoreng shoela'ng foromeletsoeng mochini le batang phehella kamore shoela'ng foromeletsoeng mochini. The batang phehella kamore shoa shoela'ng foromeletsoeng mochini e arotsoe ka mefuta e 'meli: otlolohileng le tse tshekaletseng. Ts'epe e entsoeng ka ho qhibilihisoa e kenngoe ka har'a hlobo ke mochini o lahlang ka tlas'a khatello ea khatello ea ho futhumatsa le ho theha, 'me tšepe e thata e ka fumanoa kamora hore hlobo e buloe.

Hot kamoreng shoela'ng foromeletsoeng mochini

Cold kamoreng shoela'ng foromeletsoeng mochini

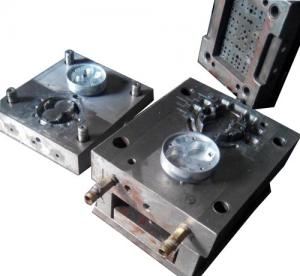

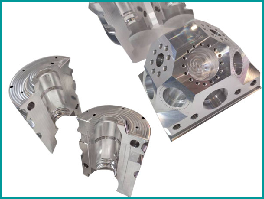

4.Die foromeletsoeng hlobo

Ka hlobo e fapaneng, maemo a sebetsang a lefu lahla li-die li thata haholo. Shoa lahla ke ho etsa tšepe e qhibilihisitsoeng e tlatsitsoe ka lehare la mochini tlasa khatello e phahameng le lebelo le phahameng, le ho ikopanya le tšepe e chesang khafetsa nakong ea ts'ebetso. Ka hona, shoa shoa lahla hlobo ho hlokahala hore ho ba le phahameng mogote mokhathala hanyetsa, mogote conductivity le qhoaele hanyetsa, ho hanyetsa ts'enyeho, tshusumetso toughness, khubelu thatafala, demoulding ntle joalo joalo. Ka lebaka leo, holim kalafo theknoloji ea shoela'ng foromeletsoeng shoela'ng hloka theknoloji e phahameng.

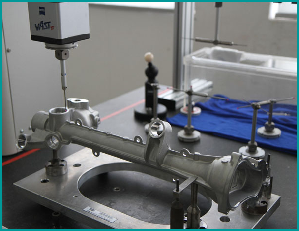

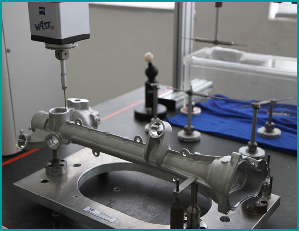

Shoa lahla hlobo

5.Post Processing le Qetella bakeng sa Likarolo tsa Die Casting

Re fana ka lits'ebeletso tse ngata tsa ho sebetsana le poso le ho phethela likarolo tsa die cast ho tsoa ho balekane ba rona ba khethiloeng:

Litšebeletso

CNC machining - paatsepama, tse tshekaletseng, ho retelehela, 5-selekane

Ho roala phofo

Liaparo tsa Metsi

EMI - RFI Ho Sireletsa

Ho roala - chrome, koporo, zinki, nikele, thini, khauta

Anodizing, Ho roala motlakase, Chromating / E sa chromating

Mocheso Phekolo, Passivation, Tumbling

Grafiken

Ts'ebetso ea Artwork ea ka tlung

Tlhatlhobo ea Silika

Khatiso ea Pad

Ho qhomisa lifaha

Khanya Mechanical Kopano, ho akarelletsa le stud le helicoil peho, O-lesale, gasket

Laser Cutting le o fatiloeng lejoeng

Manala

Ho roala motlakase le ho hlahloba silika