Likarolo tsa tšepe ke li-block tsa tšepe, li-shafts tsa tšepe, maqephe a tšepe, khetla ea tšepe, jj. tse entsoeng ka thepa ea tšepe.

Lisebelisoa tsa likarolo tsa tšepe: tšepe le litšepe tse sa sebetseng (kapa tšepe tse se nang litšepe). Metal e na le litšobotsi tse ntle haholo tseo thepa e seng ea tšepe e kang polasetiki, lehong, fiber le tse ling, tse ke keng tsa khutlisoa lihlahisoa tsa indasteri.

1.Ts'ebetso e ntle haholo, e sebelisetsoang ho etsa likarolo tse tsamaisang, joalo ka motlakase oa motlakase, switjha ea motlakase, socket.

2. Mocheso o motle oa mocheso, o ka sebelisoa ho etsa likarolo tsa mocheso oa mocheso mochining oa mochini, joalo ka siling ea mocheso, lehare la enjene, jj.

3. Polasetiki e ntle, e ka fetoha polasetiki ea thepa ea tšepe, likarolo tsa mochini o sebetsang oa libopeho tse fapaneng.

4. Molemo weldability.

5. Lisebelisoa tsa tšepe li na le thepa e phahameng ea mochini, matla a phahameng le thatafalo.

6. Tshepe e na le ntlha e qhibilihang haholo 'me e ka khona ho sebetsa bakeng sa tikoloho e phahameng ea ts'ebetso ea mocheso.

7. Likarolo tsa tšepe li ka fumana ho nepahala ha tlhakore le boleng ba bokaholimo, tse atisang ho sebelisoa ho etsa likarolo tsa mochini o nepahetseng.

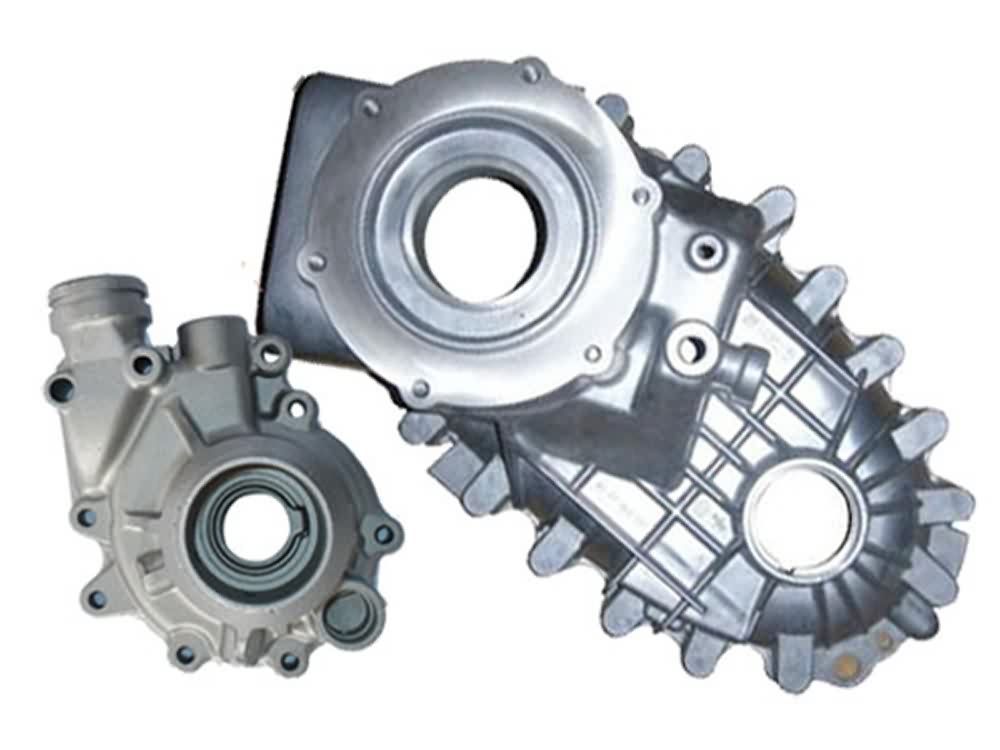

Likarolo tsa tšepe li sebelisoa haholo lisebelisoa tsa mochini, lisebelisoa tsa elektroniki, ho aha likepe, ho fofa le thepa ea lapeng. Likarolo tsa tšepe tseo re li etsetsang bareki ba rona ke tse latelang: Shaft, gear, die casting, sintering, sheet sheet

Likarolo machined

Likarolo tsa likarolo tse shoeleng

Tapa likarolo

Likarolo celik

Likarolo sebetsa ka ho nepahetseng tšepe

Theko ea tšepe

Lisebelisoa tsa liboko

Likarolo tsa aluminium die die

Zinki motsoako shoa likarolo lahleloa

Likarolo lakane tšepe

Lisebelisoa tsa theknoloji ea likarolo tsa tšepe Tšoanang le ho retelehela, siloa, betloa ha, foromeletsoeng, ho sila, CNC machining, CNC CNC CNC setsi ba machining sebetsa tloaelehileng.

Ts'ebetso ea kalafo ea bokaholimo

1. Anti ts'enyeho le anti mafome kalafo: a phehile ba batsho le a phehile putsoa o boetse o bitsoa phosphating kalafo, e le hore likarolo tšepe na le ho hanyetsa ts'enyeho le mafome li sa jeng.

2. Phekolo e thatafatsang: mokhoa oa kalafo oa ho eketsa ho thatafala ha likarolo tsa tšepe: bokaholimo ba carburization bo amoheloa ho eketsa bokaholimo ba likarolo tsa tšepe, 'me' mala oa bokaholimo o tla fifala kamora ho chesa; Ho tima kalafo ho ka eketsa thatafalo;

3. vacuum mocheso kalafo ka ntlafatsa thatafala ka kakaretso.

Mestech e fa bareki moralo le ts'ebetso ea likarolo tsa tšepe, motsoako oa aluminium, motsoako oa koporo, motsoako oa zinc le likarolo tse ling tsa tšepe. Haeba u na le lihlahisoa tsa tšepe le likarolo tseo u ka li rekang, ka kopo ikopanye le rona.